NINGBO XIANGHAI KITCHENWARE CO.,LTD

Our company can customize different types of weld studs, such as different materials, different outer diameter, different length of single point toothless nail, three point toothless nail, six point toothless nail and so on. The price and delivery time are negotiated when signing the contract. The price and delivery time as our fastest.

The name of weld studs: the national standard is called: PT type welding stud, usually called welding screw, welding stud, planting stud, welding screw, energy storage screw, capacitance energy storage welding, touch welding studs, etc.

Aluminum has good electrical conductivity, thermal conductivity, corrosion resistance, conducive to deformation characteristics and a large specific strength, so it has been widely used in industry.

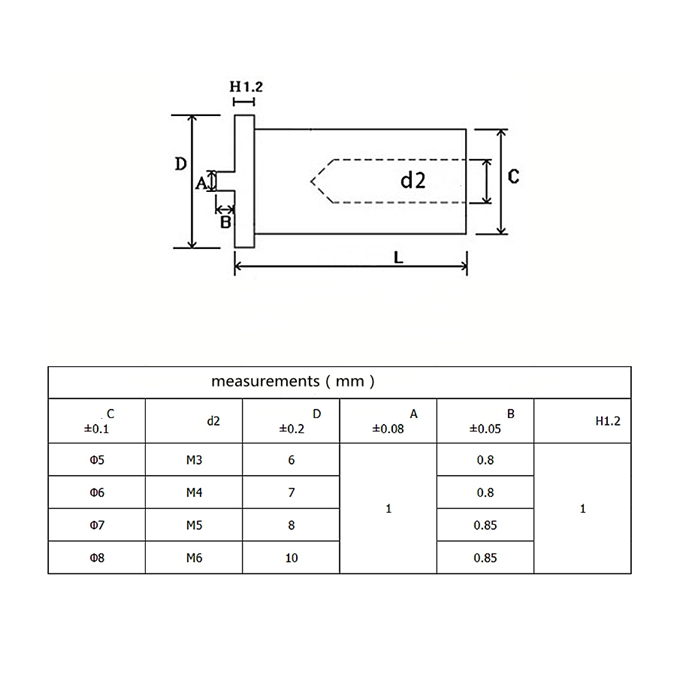

Some measurements of our common standard Aluminum welding studs, most are customized by customer.

Waiting for your contact

Cares and notes for Aluminum welding Studs:

Pure aluminum studs are relatively soft in texture. Therefore, when the tip ignition impinges on the workpiece during welding, deformation may occur, thus causing interference to the welding process.

In order to facilitate energy storage aluminum welding stud, the prerequisites:

---- The surface of the workpiece is clean and not rough;

---- stud front surface clean;

---- STUD and gripper, workpiece and ground clamp contact is not a problem and must prevent arc deflection blowing

---- Oxide film has been removed

In principle, pull-arc short-period welding should be used for aluminum nail welding with a diameter of more than 8mm, and the upper limit of diameter is 12mm.

Why we do short cycle welding:

-- The Easy oxidation characteristic of Aluminum

-- Short welding time, high instantaneous current

Mass production

The company adopts the most advanced equipment to produce, Raw materials are from the famous domestic steel mills works

Packing

According to the national standard (GB), German standard (DIN), American standard (ANSI), Japanese standard (JIS), international standard (ISO) or according to the customer's drawing to sample processing

Others we can supply

- with high strength,

- corrosion resistance,

- high temperature resistance,

- durable good characteristics.