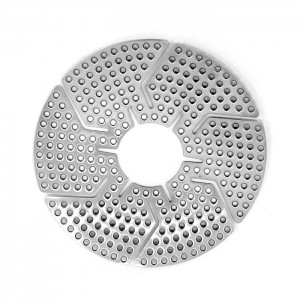

Induction Plates for Stamped Aluminum Cookware

Stamping Process: Stamped aluminum cookware is made by mechanically pressing (stamping) a sheet of aluminum alloy into shape using a large press and dies. This results in a lightweight, uniform, and thin-walled product like pots, pans, and bowls.

The Induction Solution: Clad or Bonded Base Plate

Since the aluminum sheet itself is thin and non-magnetic, the induction-compatible base is typically added as a separate layer. The most common methods are:

- Disk-Bottom Bonding: A pre-formed, multi-ply disk (often containing layers of magnetic stainless steel or iron) is bonded to the bottom of the stamped aluminum body. This disk is usually applied through high-pressure bonding, welding, or crimping.

- Cladding (For Multi-Ply Stamping): In higher-end stamped cookware, the aluminum sheet might be part of a multi-ply "clad" sheet. In this case, the sheet itself could be a sandwich (e.g., stainless steel/aluminum/stainless steel) where the outer layer is a magnetic stainless steel. This entire clad sheet is then stamped into shape, creating a fully induction-compatible body with excellent heat distribution.

Key Characteristics of the Induction Plate:

- Material: Usually austenitic magnetic stainless steel (like 430-grade induction disks) or pure low-carbon steel (iron).

- Integration: Often a separate component bonded to the aluminum.

- Performance: Provides a flat, magnetic surface for induction coupling. Heat is generated in this plate and then transferred to the aluminum body. The evenness of heating depends on the quality of the bond and the thickness of the aluminum.

Die-Casting Process: Die-cast aluminum cookware is made by forcing molten aluminum alloy under high pressure into a steel mold (die).

This allows for creating complex, thick-walled shapes with integrated handles and detailed features, common in items like dutch ovens, grill pans, and casserole dishes.

However, this kind of production needs high pressure and production reauirements. The production cost would be high. Many factories choose another way.

- Secondary Attachment:

- Less common, but sometimes a plate can be bonded to the finished casting using specialized techniques, though encapsulation is generally more robust for this manufacturing type.