How to choose the Induction bottom plate factory?

Firstly, let’s know some details of induction base plate.

1.Production process

The production process of stainless steel composite film: a. Material preparation: select high-quality stainless steel materials, commonly used stainless steel 410 and 430, etc. b. Material cutting: Cut the stainless steel material to the required size. You can use shears or cutting tools to operate. c. Place the cut induction base plate on the punch machine, and the punch machine will make the specified shape and pattern. Usually punching holes or designing patterns. d. Trimming and trimming: Trim and trim the induction base to make its edges flat and neat. e Inspection and packaging: Conduct quality inspection on the induction bottom plate, and then package it after passing it, and finally ship the goods.

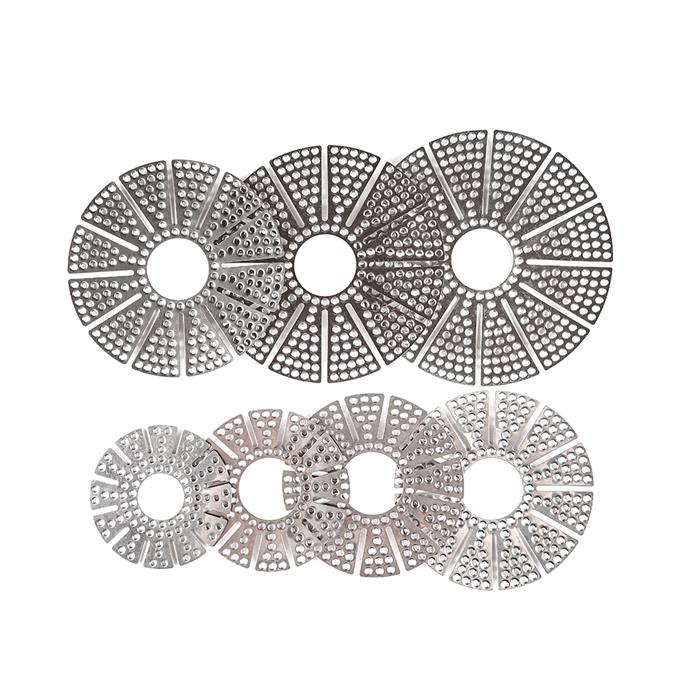

2. The types of induction hole plates

Our company produces hundreds of types of induction hole plates in various sizes and shapes. In order to match the bottom of the aluminum die-cast cookware, holes of different diameters can be designed. The diameter of the bottom of each pot is different, so there are 5-10 different sizes of the induction steel plate for each shape.

The flower-shaped induction bottom disk can meet customers' aesthetic requirements for the bottom of aluminum pots. The square induction bottom sheet can be adapted to cookware with a square bottom, such as square frying pans and square fish plates. There are also some oval-shaped induction sheets that can fit oval frying pans more closely. The bottom of the cookware is heated more evenly and the cooking experience is better. (www.xianghai.com)

3.Usage appliance

The composite film is mainly used on the bottom of aluminum cookware. Due to the popularity of aluminum cookware, more and more people prefer non-stick aluminum pots. But a simple aluminum pot cannot be used on an induction cooker. Therefore, smart humans designed a composite film and used a machine to press the stainless steel plate tightly on the bottom of the aluminum pot to achieve the magnetic conductivity effect.

4. Advantages and Disadvantages

Although the composite film is corrosion-resistant, magnetically conductive, and allows the bottom of the cookware to be heated more evenly, it also has some disadvantages. Since the induction bottom plate and cookware are pressed and synthesized at a later stage, if some factories have deficient production techniques, the composite film may fall off. Cause damage to the stove or more serious problem. Therefore, you need to pay attention when using it.

Post time: Oct-17-2023