Chinese factories gain a strong advantage at Indonesia expos by prioritizing quality cookware spare parts. Buyers recognize a durable wood effect bakelite knob, a reliable wok pan bakelite handle, and a sturdy Aluminum rivet as signs of excellence. Consistent performance from an Aluminum kettle spout or a well-crafted Aluminum kettle strengthens trust and supports lasting partnerships.

Key Takeaways

- Chinese factories win buyer trust at Indonesia expos by showcasing durable and reliable cookware spare parts like bakelite knobs and aluminum rivets.

- High-quality parts ensure smooth product demonstrations, helping factories stand out and attract more orders from Indonesian buyers.

- Implementing strict quality control and meeting Indonesian standards boosts factory reputation and builds long-term business partnerships.

Impact of Quality Cookware Spare Parts on Exhibition Success

Building Buyer Trust and Interest

Indonesian buyers attend expos with high expectations. They look for suppliers who deliver consistent quality. When Chinese factories showcase premium cookware spare parts, buyers notice the attention to detail. A well-made bakelite knob or a sturdy aluminum rivet signals reliability. Buyers often compare products side by side. They trust suppliers who present flawless components.

Tip: Displaying samples of cookware spare parts allows buyers to inspect quality firsthand. This practice increases transparency and builds confidence.

Buyers value suppliers who invest in quality. They prefer long-term partnerships with factories that maintain high standards. Trust grows when buyers see that every part meets their requirements. Factories that focus on quality attract more interest and inquiries during expos.

Ensuring Reliable Product Demonstrations

Product demonstrations play a crucial role at expos. Factories use these opportunities to highlight the performance of their cookware spare parts. Reliable components ensure smooth demonstrations. Handles must remain secure, and spouts should function without leaks. Any failure during a demonstration can damage a factory’s reputation.

A simple table illustrates the difference between high-quality and low-quality demonstrations:

| Component | High-Quality Demo Outcome | Low-Quality Demo Outcome |

|---|---|---|

| Bakelite Handle | Stays cool, remains firm | Gets loose, heats up |

| Aluminum Rivet | Holds parts securely | Breaks under pressure |

| Kettle Spout | Pours smoothly | Leaks or drips |

Successful demonstrations convince buyers of product reliability. They see how cookware spare parts perform under real conditions. Factories that avoid technical issues during demos gain a competitive edge. Buyers remember positive experiences and are more likely to place orders.

Meeting Indonesian Market Expectations for Cookware Spare Parts

Understanding Indonesian Buyer Standards

Indonesian buyers set clear standards for cookware spare parts. They expect products to withstand daily use and resist common issues such as rust, breakage, or fading. Buyers often inspect the finish, weight, and fit of each component. They value handles that remain cool, knobs that feel sturdy, and rivets that hold parts together securely. Factories must understand these preferences to meet market demands.

A table highlights key expectations:

| Buyer Expectation | Description |

|---|---|

| Durability | Withstands frequent use |

| Safety | No sharp edges or loose fittings |

| Appearance | Consistent color and smooth finish |

| Functionality | Fits and works as intended |

Factories that align their products with these standards gain respect and trust from Indonesian buyers.

Avoiding Pitfalls of Low-Quality Spare Parts

Low-quality cookware spare parts create problems for both buyers and suppliers. Buyers may experience product failures, leading to complaints and returns. Suppliers risk losing future business and damaging their reputation. Common pitfalls include weak handles, poorly fitted knobs, and rivets that break under pressure.

Note: Factories should conduct thorough inspections before shipping products to Indonesia. This step helps prevent costly mistakes and ensures customer satisfaction.

Factories that avoid these pitfalls build stronger relationships and increase their chances of success at expos.

Competitive Advantage with Quality Cookware Spare Parts at Expos

Standing Out Among Competitors

Chinese factories that focus on quality cookware spare parts gain a clear edge at Indonesia expos. Buyers notice advanced features and innovative designs, which reflect a factory’s commitment to excellence. Many Indonesian buyers compare products from different suppliers. Factories that offer durable handles, safe materials, and customization options attract more attention. They often receive higher ratings for reliability and value for money.

Buyers appreciate warranties and after-sales services. These offerings reduce hesitation and build trust, especially in markets where repair and spare parts availability matter.

A table highlights attributes that help factories stand out:

| Attribute | Description |

|---|---|

| Durability | Handles made from Bakelite last longer and resist damage. |

| Safety | Non-toxic materials ensure user safety. |

| Innovation | Factories use advanced technologies and offer customization. |

| Customer Satisfaction | Reliable delivery and competitive pricing lead to excellent ratings. |

| Value for Money | High quality comes with reasonable prices. |

Factories that emphasize these qualities overcome stereotypes about low-quality products. They earn respect and recognition from buyers who value both performance and service.

Building Long-Term Business Relationships

Quality-focused factories build lasting partnerships with Indonesian buyers. Consistent product standards and cultural alignment foster loyalty. Buyers trust suppliers who understand their expectations and deliver reliable cookware spare parts. Extended warranties and free after-sales support encourage repeat business.

Factories that maintain high standards receive positive feedback and referrals. They create a reputation for dependability and innovation. Over time, these relationships lead to increased orders and market acceptance. Buyers prefer working with suppliers who prioritize quality, certifications, and customization.

Practical Steps to Ensure Quality in Cookware Spare Parts

Implementing Quality Control Measures

Leading Chinese factories establish robust quality control systems to guarantee high standards in cookware spare parts manufacturing. They follow internationally recognized certifications such as BSCI, FDA, and LFGB. Dedicated quality control staff monitor every stage, from raw materials to finished products. Factories conduct random manual inspections in each workshop, ensuring that defects do not reach buyers. Double inspection measures help achieve a product qualification ratio above 90%.

The manufacturing process involves several meticulous steps:

- Cold pressing with precision

- First wash to remove grease

- Rim processing

- Hand polishing

- Sandblasting for better coating adhesion

- Second cleaning to remove grains

- Interior and exterior coating application

Factories also perform oven heating-up and drop tests, appearance checks, and handle fatigue resistance tests. These steps confirm that each component meets safety and durability standards.

Tip: Factories should maintain strict documentation and regular audits to verify compliance with quality certifications.

Sourcing and Testing Cookware Spare Parts

Factories source raw materials from trusted suppliers and evaluate production areas for machinery, process flow, and workforce expertise. Warehousing conditions receive careful assessment to prevent quality compromise. Multi-stage inspections begin with raw material sourcing and continue through final product checks. Independent quality control teams supplement in-house staff, maintaining accountability.

A proper inspection plan covers major components and final sampling. Factories communicate inspection plans clearly to suppliers, reducing resistance. Product inspections follow ISO2859-1 standards with defined Acceptance Quality Limits (AQL). If defects appear, suppliers inspect and sort the entire batch or notify buyers if re-production is impossible.

| Inspection Step | Purpose |

|---|---|

| Thickness Inspection | Ensures correct dimensions |

| Coating Test | Confirms adhesion and durability |

| Handle Fatigue Test | Verifies long-term reliability |

| Non-stick Performance | Assesses cooking quality |

Feedback from QC reports helps factories adjust inspection strictness and improve communication. Consistent quality standards build trust with Indonesian buyers and support long-term business growth.

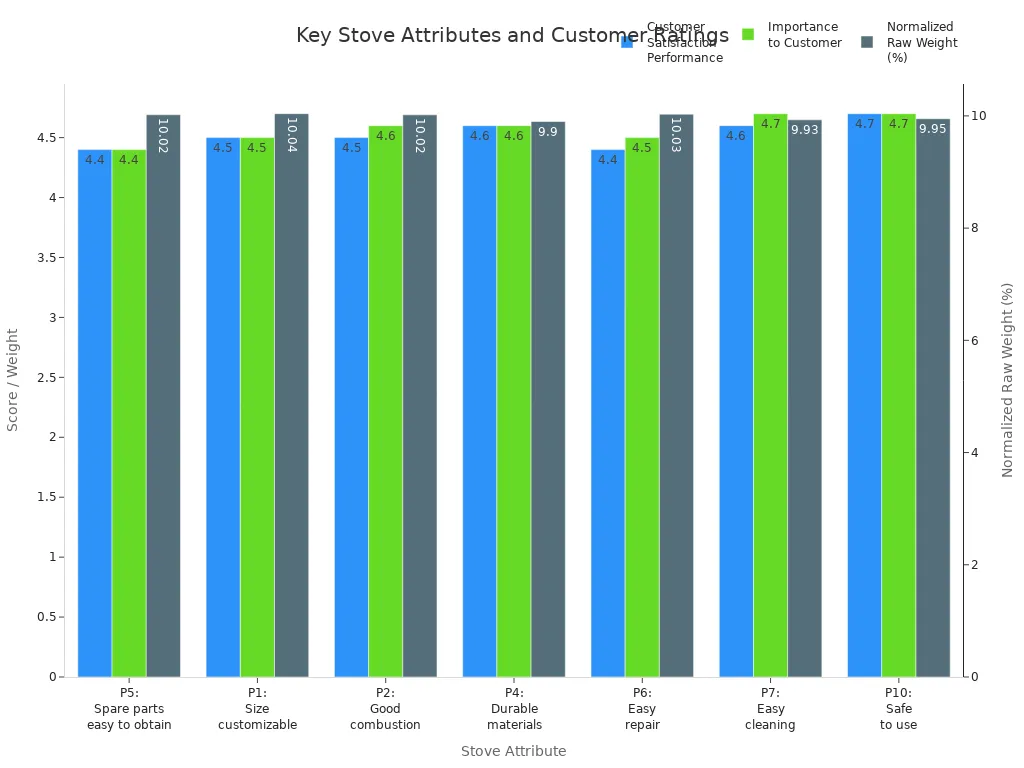

Prioritizing quality remains essential for exhibition success and long-term growth in Indonesia. The table below shows that easy access to spare parts ranks among the top factors for customer satisfaction and importance. High standards improve reputation and future opportunities. Factories should review and upgrade quality before expos.

| Attribute | Customer Satisfaction | Importance | Normalized Weight |

|---|---|---|---|

| Easy to obtain spare parts | 4.4 | 4.4 | 10.02% |

FAQ

What certifications do Indonesian buyers expect for cookware spare parts?

Buyers in Indonesia often look for BSCI, FDA, or LFGB certifications. These certifications show that factories meet international safety and quality standards.

How can factories prove the quality of their spare parts at expos?

Factories can provide test reports, display inspection records, and offer live demonstrations. These actions help buyers verify product reliability and performance. Please contact www.xianghai.com

Why do Indonesian buyers value easy access to spare parts?

Easy access to spare parts reduces downtime and repair costs. Buyers prefer suppliers who guarantee quick delivery and consistent availability.

Post time: Aug-12-2025